We created a machine named Chop-Chop to pull this whole thing off.

To make a smooth, three dimensional surface, we needed the ability to cut each dowel at a different length. With over 20,000 dowels, CNC capability was essential. After a few concepts were sketched, we settled on a JET bandsaw that was augmented with a custom made digital stop.

Chop-Chop reads each dowel length from the SD card, then the stepper motor turns a timing belt and stop to the position that matches the dowel length. Once the dowel is cut, the miter sled hits a switch, signaling the digital stop to move to the next position. Once you’re in a rhythm, you just simply, chop, chop, chop….

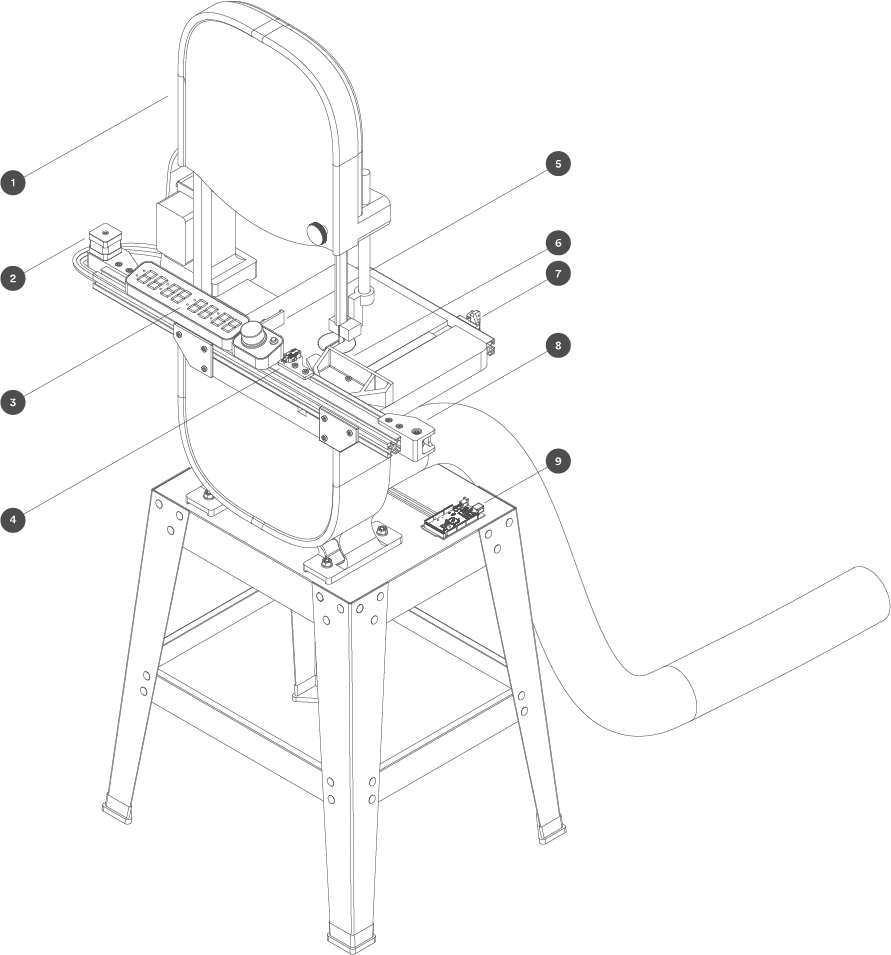

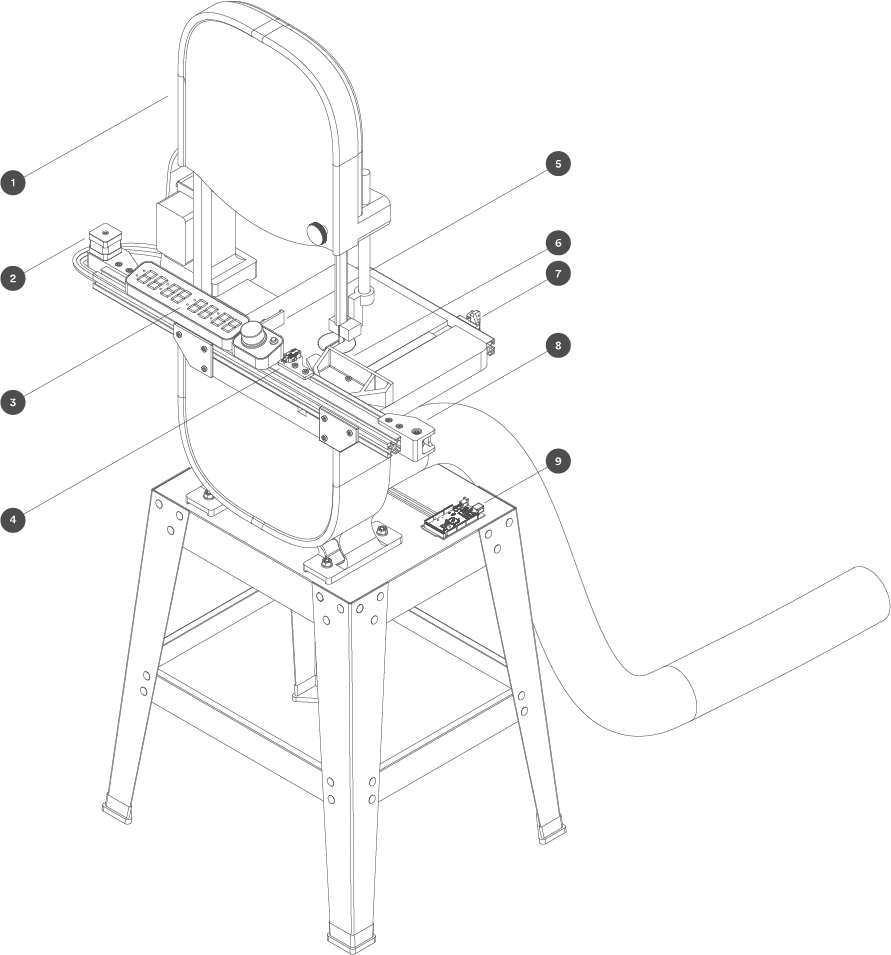

1 - Band Saw

JET JWBS-14OS 14”

2 - Drive Assy

NEMA 17 Stepper Motor

3d Printed Housing

Timing Pulley, GT2 16T - MISUMI

Timing Belt, GT2 - MISUMI

3 - Display Module

2, 1.2” 7-Segment Displays - Adafruit

3d Printed Housing

Transparent Acrylic

Control Knob

Button

4 - Zero Switch

3d Printed Housing

Limit Switch - Omron

5 - Stop Assy

3d Printed Stop

AL Extrusion Slider - Misumi

6 - Miter Sled

3d Printed Support

Stock rail - JET

7 - Stroke Limit Switch

3d Printed Support

Limit Switch - Omron

8 - Idler Assy

3d Printed Housing

Timing Pulley, GT2 16T - Misumi

Shaft with C—Clips - Misumi Bearings - Misumi

Fasteners - McMaster-Carr

9 - Microcontroller

Arduino MEGA

Big Easy Stepper Driver - Brian Schmalz

SD Reader - Adafruit

Microcontroller

Chop-Chop runs on an Arduino MEGA, Big Easy stepper driver, and an SD reader. A protoshield provides easy connection to the limit switch inputs.